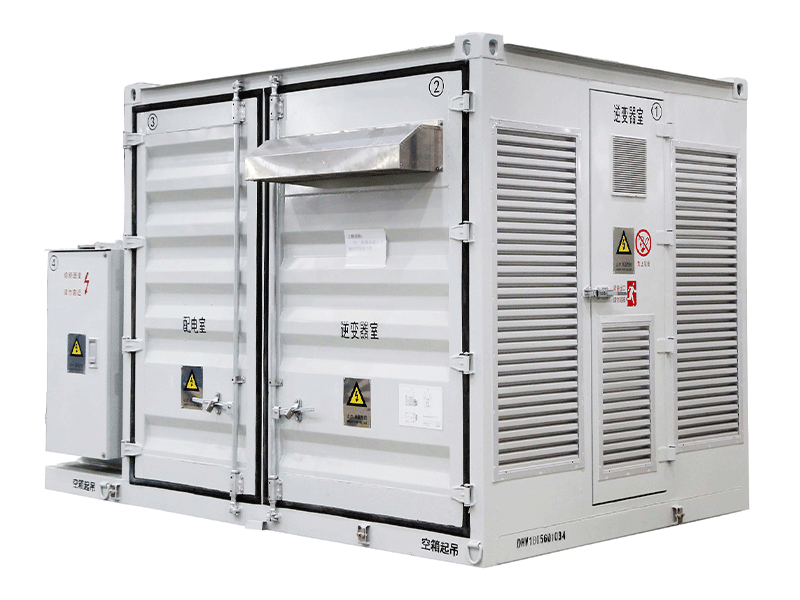

Photovoltaic Inverter

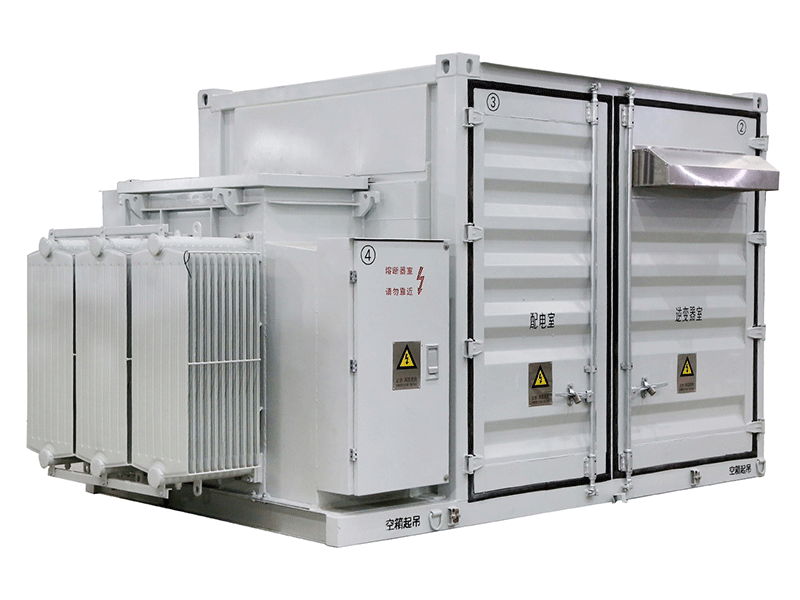

Step up Integrated Transformer

FUTURE-SOLUTION

Photovoltaic inverter

step-up transformer

Eliminating 35kV medium-voltage switchgear reduces system costs by 22%.

Epoxy resin vacuum casting (partial discharge <5pC)

Scenario-based transformer technology solutions

Transformer Solution:

Amorphous Alloy Core (No-Load Loss 0.28W/kg)

Stainless Steel Corrugated Fuel Tank (C5M Corrosion Resistance Grade)

Top Shade and Heat Dissipation Wing Design (Reduces Internal Temperature by 15°C)

Fuel tank triple coating: zinc-rich primer + epoxy micaceous iron oxide + polyurethane topcoat

Casing silicone rubber composite insulation (hydrophobicity Class HC1)

Measured data: Salt spray test for 3000 hours, corrosion rate <0.5μm/year

Synthetic ester oil (freezing point -45°C, compared to -22°C for standard mineral oil)

Winding inter-turn insulation thickened by 0.5mm (to prevent cold cracking)

Operational Verification: No faults recorded during cold start at -40°C

1.Photovoltaic Inverter Integrated Pad-Mounted Transformer

Pad-Mounted Transformer

Oil-Immersed Transformer

2.Photovoltaic Inverter Step Up Integrated Compact Substation

3.Photovoltaic Energy Storage

Renewable energy

innovations and insights.

Global Movement