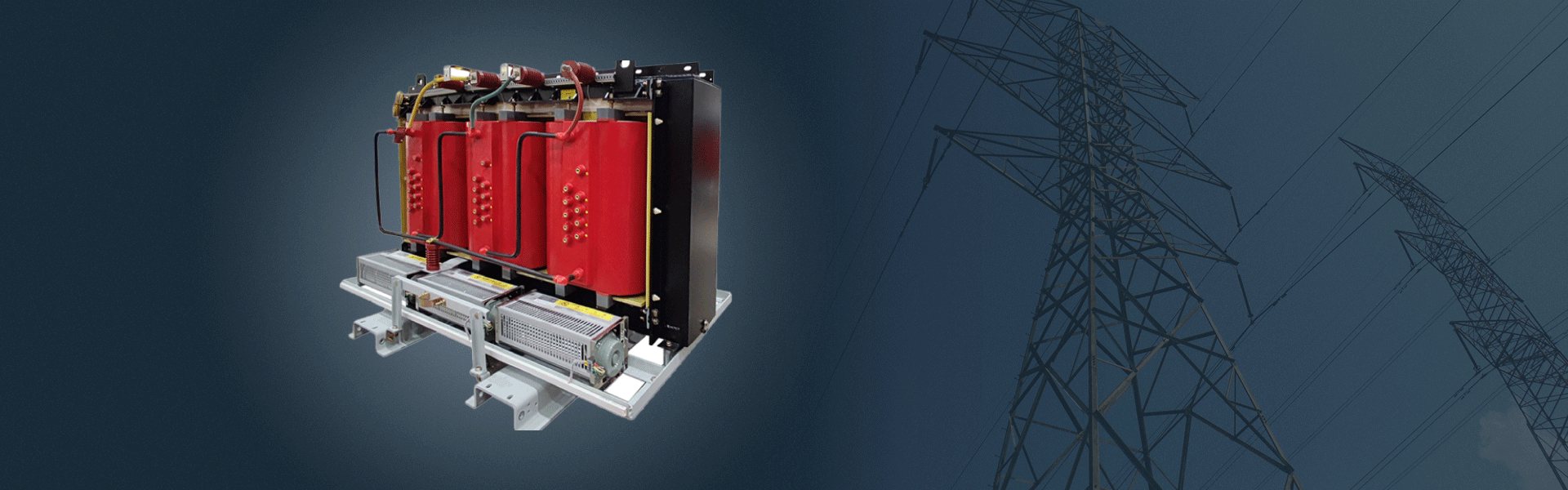

Amorphous Alloy Dry-Type Transformer

What Are Amorphous Alloy Transformers?

The core uses iron-based amorphous metal ribbons (0.02-0.04mm thick) formed via ultra-rapid cooling. Their disordered atomic structure (glass-like) eliminates grain boundary losses, improving magnetization efficiency by 40-60% over silicon steel.

1.

Ultra-Low Losses, Proven Savings

70-80% lower no-load loss: Amorphous alloy’s resistivity is 3-6x higher than silicon steel. Example: 10kV/400kVA amorphous transformer no-load loss = 215W vs. 570W for silicon steel.

Lower TCO: Despite 30% higher upfront cost, annual energy savings of $7,000+ yield a 3-5 year payback.

2.

Eco-Friendly, Carbon-Neutral Alignment

CO₂ reduction: 5-8 tons/year per unit; SO₂ reduced by 0.1 tons.

Sustainable lifecycle: 1L oil saved per kg of alloy produced; 100% recyclable cores.

3.

High Reliability in Harsh Conditions

Harmonic tolerance: SCRBH15 models operate stably under THD ≤5% (ideal for PV inverters/VFDs).

Robust protection: IP23-rated for -40°C to +45°C, 100% humidity.

4.

30-Year Lifespan & Maintenance-Free

Slow insulation aging: 1/3 the degradation rate of silicon steel.

Oil-free design: Eliminates leaks; IoT temperature monitoring.

Solar/Wind Step Up

Energy Storage

Commercial hubs

Rail Transit

Steel Mills

Oil Refineries

Why choose

Pearl Electric

Strong Production Capacity

Simultaneously possesses the production capacity for silicon steel and amorphous alloy transformers.

Rich Production Experience

Rich experience in dry-type transformer production, up to 30MVA 69kV