Traction Rectifier Dry-Type Transformer

1.The traction dry-type transformer and The traction rectifier form the traction unit together

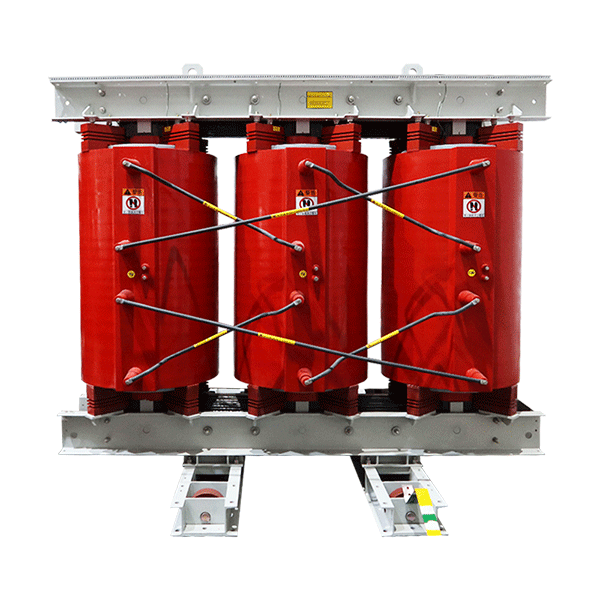

2.Class VI load rating

3.12-pulse or 24-pulse parallel connections can reduce the harmonic content of the system

4.The traction rectifier transformer not only plays a step-down role, but also turns the three-phase AC power into a multi-phase AC power supply to the rectifier for rectification

5.Transformer requirements:

Grid side voltage 10kV, 33kV or 35kV; Valve side voltage 1.18kV (DC 1500V) or 0.59kV (DC 750V);

Insulation Grade: Class F or Class H; Short circuit impedance: 8%; Partial discharge: <10pC

6.The use of epoxy resin to pour dry-type transformers has high reliability requirements

What are Pearl Electric good at?

Simultaneously possesses production capabilities for silicon steel and amorphous alloy traction transformers.

Extensive experience in coordination and system installation.

Pearl Electric has rich application performance of energy feed transformers, and is used in many subway lines with many energy feed converter manufacturers.

Simulation or test verification of harmonic content, ripple coefficient, system power factor and efficiency are all required

Our traction transformer, featuring two parallel-connected traction transformers, only requires the replacement of the connecting rod to achieve a ±7.5° phase angle switch, demonstrating good interchangeability.

Since 2007, we have accumulated over 18 years of experience in the production of traction dry-type transformers.

Pearl Electric was founded in 1958, we are one of the top five dry-type transformer manufacturers in China.

Transformer for Kinetic Energy Recovery Inverter

By replacing the conventional resistive braking, the braking energy of the subway/train is returned to the grid through an inverter device, thereby realizing energy recovery and reuse

Technical characteristics:

1. Intermittent working system, repeated impact load

According to the working system, calculate the transformer capacity and operational temperature Rise

Epoxy resin casting has a strong impact resistance and electrical performance

2. Due to the influence of inverter power supply, harmonics are inevitable

Optimize the selection of magnetic flux density to reduce the influence of harmonics

Consider the effects of harmonic currents during the temperature rise calculations

*New applications: Increase transformer impedance and integrate reactors. The transformer can simultaneously accommodate both traction rectification and energy feedback requirements.