English

Views: 0 Author: Site Editor Publish Time: 2025-10-10 Origin: Site

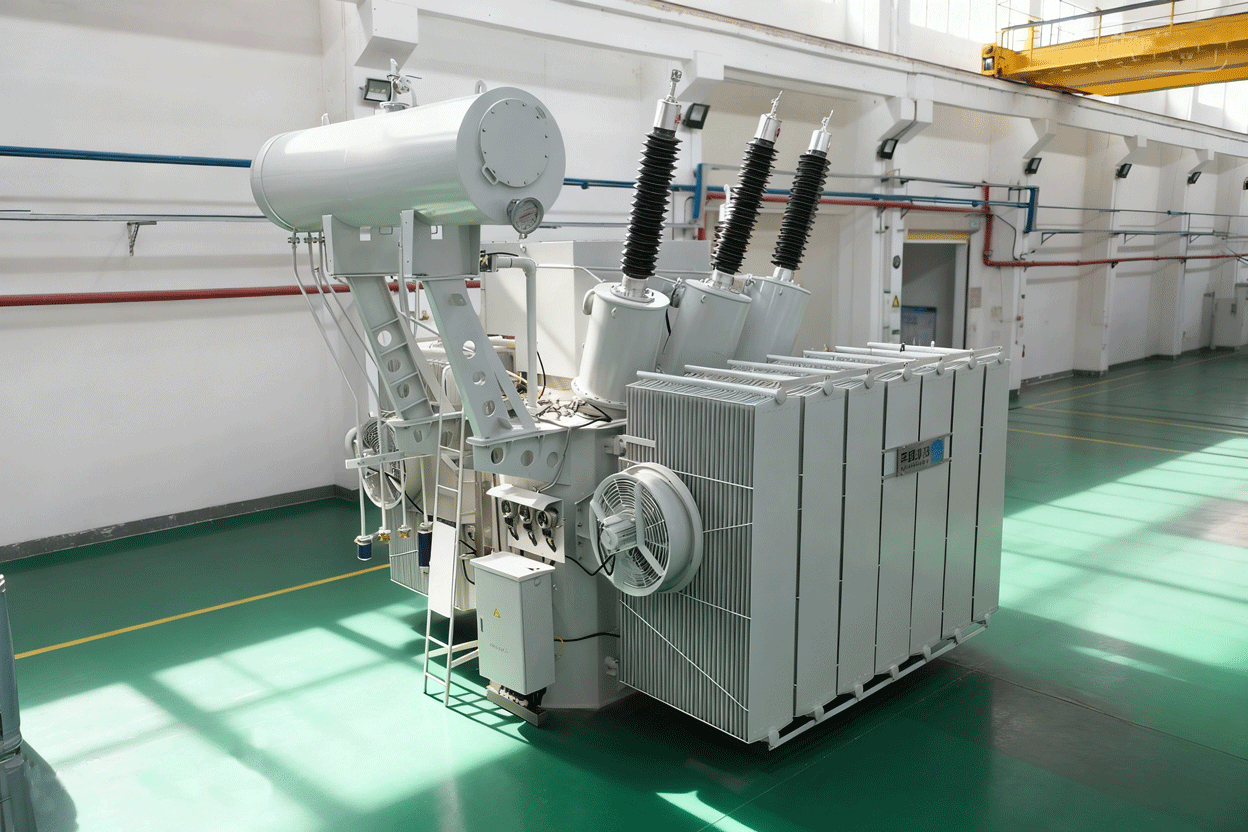

When you look at a large power transformer, one of the first things you'll notice is the robust tank that houses it. A critical question often follows: Why is this transformer filled with oil? Is it for lubrication? For weight?

The answer is far more crucial to the stability of our electrical grid. Transformer oil, or insulating oil, is not just a filler; it's the lifeblood of the transformer, performing two indispensable functions: insulation and cooling.

As a leading power transformer manufacturer, we will break down these two primary roles and explain why this liquid is so vital for efficient and safe power distribution.

Inside a transformer, you have high-voltage windings in very close proximity. The core and the windings must be electrically isolated from each other to prevent short circuits, which would be catastrophic.

The Insulating Barrier: Air is a poor insulator for the extremely high voltages (like 66kV, 132kV, or higher) that power transformers handle. Transformer oil, however, has excellent dielectric strength—meaning it can withstand much higher electrical stress without breaking down.

How it Works: By immersing the core and windings in oil, we create a highly effective insulating barrier. This oil penetrates the porous paper insulation (kraft paper) on the windings, preventing electrical arcs and short circuits that would instantly destroy the transformer.

In short, the oil allows the transformer to handle massive electrical loads safely and reliably.

Transformers are not 100% efficient. As electricity flows through the windings, resistance causes heat to build up—a phenomenon known as copper and iron losses. If this heat isn't removed, it will rapidly degrade the insulation and eventually melt the windings, leading to failure.

The Cooling Process: Transformer oil acts as a highly effective coolant. It circulates naturally or through pumps, absorbing heat from the core and windings.

Heat Dissipation: The heated oil rises to the top of the tank, transferring its heat to the tank's walls. From there, the heat is dissipated into the surrounding air through cooling fins or radiators. The cooled oil then sinks back down to absorb more heat, creating a continuous natural convection cycle.

This process is so effective that it keeps the transformer operating within its safe temperature range, ensuring a long service life—often decades.

Beyond its primary roles, transformer oil serves a third, incredibly valuable function: it is a diagnostic window into the transformer's health.

Through a process called Dissolved Gas Analysis (DGA), we can sample the oil and test for the presence of specific gases.

What it Reveals: Different faults (like arcing, overheating, or partial discharges) produce unique gas signatures within the oil.

Proactive Maintenance: By analyzing these gases, our engineers can identify developing problems before they cause a costly failure. This allows for predictive maintenance, preventing unplanned outages and extending the transformer's operational life.

Historically, petroleum-based mineral oil was the standard due to its excellent insulating and cooling properties. Today, there are also synthetic esters and natural (vegetable) esters, known as "bio-based oils," which are more environmentally friendly and have higher fire points, making them suitable for specific applications.

So, the next time you see an oil-filled transformer, you'll know it's not just a simple tank. The oil inside is a sophisticated, multi-tasking fluid that:

Insulates to prevent electrical faults.

Cools to prevent thermal degradation.

Protects by enabling predictive maintenance.

At Pearl Electric, we engineer our power transformers with a deep understanding of these fundamental principles. The careful selection and management of transformer oil are integral to delivering products that are reliable, efficient, and built to last for decades, forming the backbone of a stable power supply.

Are you looking for a reliable, high-performance power transformer for your project? [Contact our expert team today] to discuss your specific requirements and discover how we can power your future.