English

Views: 0 Author: Site Editor Publish Time: 2025-04-27 Origin: Site

High voltage transformers serve as critical equipment in power transmission and industrial production, with applications spanning energy, manufacturing, healthcare, and other vital sectors. This article explores the essential roles of high voltage transformers in modern society through technical principles, application scenarios, and industry case studies.

Learn more: [How to Choose a High Voltage Transformer? 5 Key Metrics Explained (2024 Practical Guide)]

I. Core Roles in Power Systems

High voltage transformers step up the 10-35kV voltage generated by power plants to 220kV or higher, significantly reducing current intensity in transmission lines and minimizing energy loss (by over 90%). For example, in China’s West-East Power Transmission Project, ultra-high voltage (UHV) transformers boost voltage to 1000kV, enabling efficient transmission over 3,000 km.

In substations, high voltage transformers perform voltage conversion and reactive power compensation:

Step-down distribution: Reducing transmission network voltage from 220kV to 10kV/35kV for regional grids.

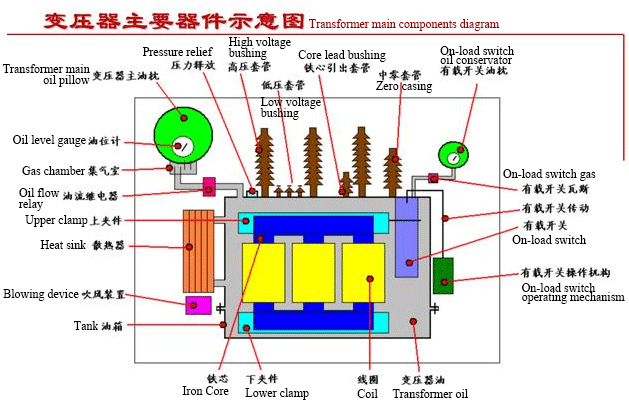

Voltage stabilization: Using on-load tap changers (e.g., ±10% adjustment range) to dynamically respond to load fluctuations and ensure grid stability.

Metallurgy: Providing 10kV-35kV operational voltage for electric arc furnaces and induction furnaces to support high-energy steel smelting.

Chemical plants: Powering electrolyzers and large compressors, such as 6-10kV dedicated transformers for chlor-alkali production.

Semiconductor fabrication: Wafer etching machines require ultra-low harmonic high-voltage power (e.g., 40kV class), with transformers meeting stringent THD <1% standards.

Laser cutting: CO₂ lasers rely on 20-50kV high-voltage transformers to generate plasma, where precision directly impacts cutting quality.

Solar farms: Inverting 0.8-1.5kV DC output from PV arrays to 35kV AC, then stepping up to 132kV grid voltage (e.g., Ningxia’s 2GW solar project).

Offshore wind: 66kV offshore substations use cast resin dry-type transformers for salt mist resistance and maintenance-free operation.

Battery storage: High voltage transformers enable bidirectional DC/AC conversion for grid frequency regulation (e.g., Tesla Megapack’s 2.5MVA transformers).

Learn more:[Dry-Type Vs. Oil-Immersed Transformers: A Comprehensive Comparison Guide (2025 Edition)]

Imaging diagnostics: X-ray and CT machines require 80-150kV power supplies, with transformers compliant to IEC 60601 medical standards for insulation and EMC.

Therapy devices: Linear accelerators for radiotherapy use pulse high-voltage transformers (nanosecond response) with <0.1% error tolerance.

Particle accelerators: CERN employs 400kV resonant transformers to create acceleration fields for particle beams.

High-voltage testing: Insulation material tests require 1000kV power frequency test transformers to simulate extreme conditions.

Condition monitoring: Integrated DGA (dissolved gas analysis) and fiber-optic temperature sensors for predictive maintenance (e.g., ABB’s TXpert™ solution).

Digital twins: 3D modeling to predict transformer lifespan, reducing O&M costs by 30%+.

Eco-friendly materials: Biodegradable ester oils replace mineral oil (fire point raised to 300°C).

High-efficiency designs: Amorphous core transformers cut no-load loss by 70%, ideal for intermittent loads like solar farms.

Conclusion:

High voltage transformers have expanded from traditional power transmission to cutting-edge fields like smart manufacturing and renewables. Their technological advancements drive industrial progress. Businesses can opt for customized solutions (e.g., high-temp or explosion-proof designs) while embracing smart and eco-friendly trends to maximize ROI.

(For high voltage transformer selection guidance or technical solutions, contact our expert team.)