English ![]()

Views: 0 Author: Site Editor Publish Time: 2025-05-08 Origin: Site

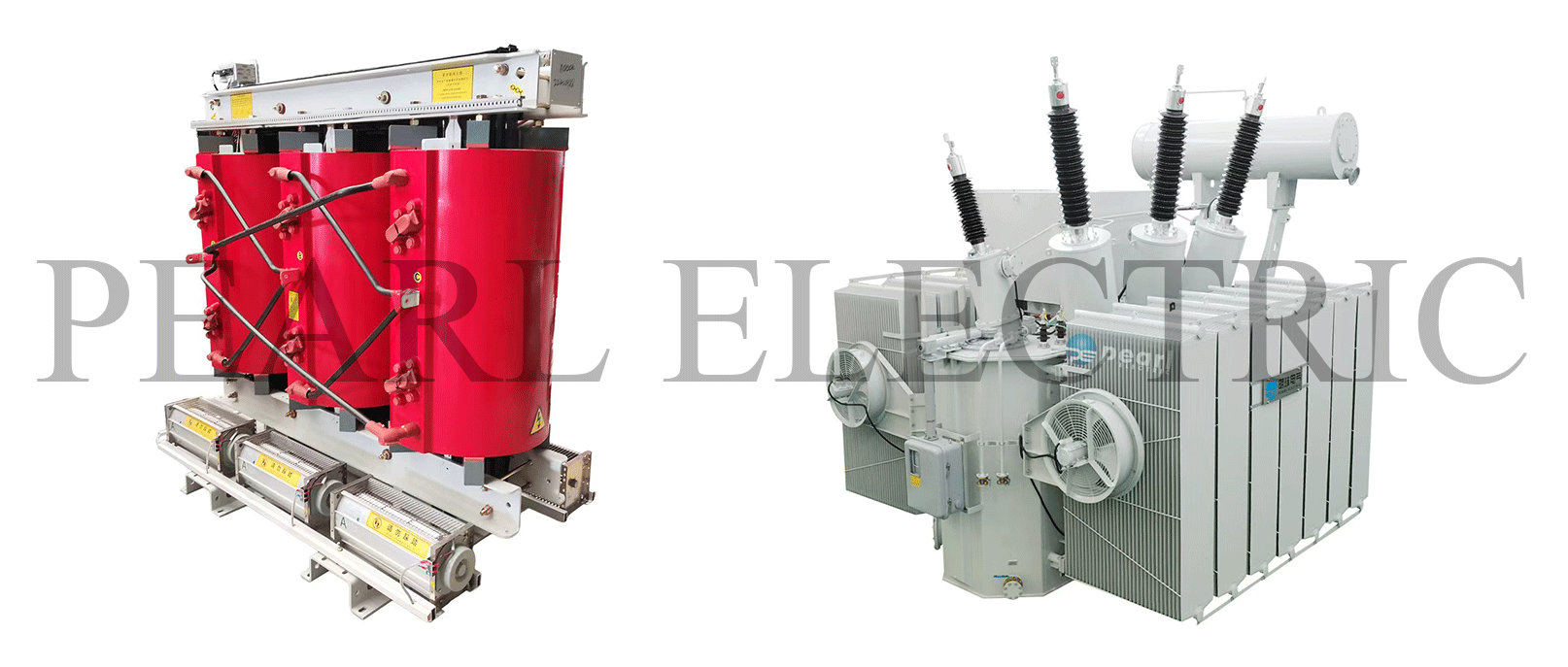

As critical components of power systems, the choice between dry-type and oil-immersed transformers significantly impacts power supply safety and cost efficiency. This guide analyzes their structural, performance, and application differences to help you make informed decisions.

Dry-Type Transformers:

Insulation: Epoxy resin casting or non-encapsulated solid insulation (e.g., Nomex paper).

Structure: Visible core/windings with silicone rubber bushings.

Oil-Immersed Transformers:

Insulation: Mineral or synthetic ester oil; fully submerged in a tank.

Structure: Sealed tank with porcelain bushings.

Type | Typical Capacity | Max Voltage | Key Applications |

Dry-Type | ≤2500kVA | 35kV (rarely 66kV) | Commercial buildings, Data centers |

Oil-Immersed | No limit (up to 1000kV) | Full voltage levels | Power plants, UHV transmission |

Cooling Efficiency:

Dry-Type: Natural/forced air cooling (limited efficiency).

Oil-Immersed: Oil circulation (superior for sustained high loads).

Overload Tolerance:

Dry-Type: ≤1.5x rated capacity (short-term).

Oil-Immersed: 30% overload for 1 hour.

Metric | Dry-Type | Oil-Immersed |

Initial Cost | 1.5x higher | Lower |

Maintenance | Low (no oil monitoring) | High (oil replacement, leak prevention) |

Lifespan | 20-30 years | 30-40 years (sealed design) |

Fire Safety: Hospitals, subways, skyscrapers (flame-retardant epoxy).

Space Constraints: Basements, compact substations (20% smaller size).

Eco-Sensitive Zones: Oil-free design compliant with RoHS.

High Power Needs: Thermal plants, industrial parks (≥10MVA).

Humid Environments: Coastal areas, mines (oil resists moisture).

Extreme Climates: Stable performance at -40°C to 45°C.

Define Requirements: Load type (continuous/shock/harmonic), environment (humidity/space).

Calculate Capacity: S = Load Power (kW) / Power Factor.

Match Features:

Fire safety → Dry-Type (SCB series)

High capacity/voltage → Oil-Immersed (S13-M series)

Cost-Benefit: Long-term → Dry-Type (low TCO); short-term → Oil-Immersed (low CAPEX).

Dry-Type:

Smart Monitoring: IoT-enabled sensors (e.g., Siemens CoolBlue).

High Voltage: Experimental 66kV models for offshore wind farms.

Oil-Immersed:

Eco-Upgrades: β-oil (fire point ≥300°C) replacing mineral oil.

Compact Design: Sealed corrugated tanks (15% smaller footprint).

Conclusion

Dry-type and oil-immersed transformers coexist as complementary solutions. With tightening regulations (e.g., EU Tier 3), dry-types dominate commercial sectors, while oil-immersed remain vital for energy infrastructure. For optimal selection, balance technical specs with lifecycle costs, and consult experts for tailored solutions.